Shandong Jiayi Machinery Sheet Metal Equipment Manufacturing Base

+86 137-0538-4901 +86 189-5381-3118 |

Shandong Jiayi Machinery Sheet Metal Equipment Manufacturing Base

+86 137-0538-4901 +86 189-5381-3118 |

Product

產(chǎn)品展示

GPS Press brake

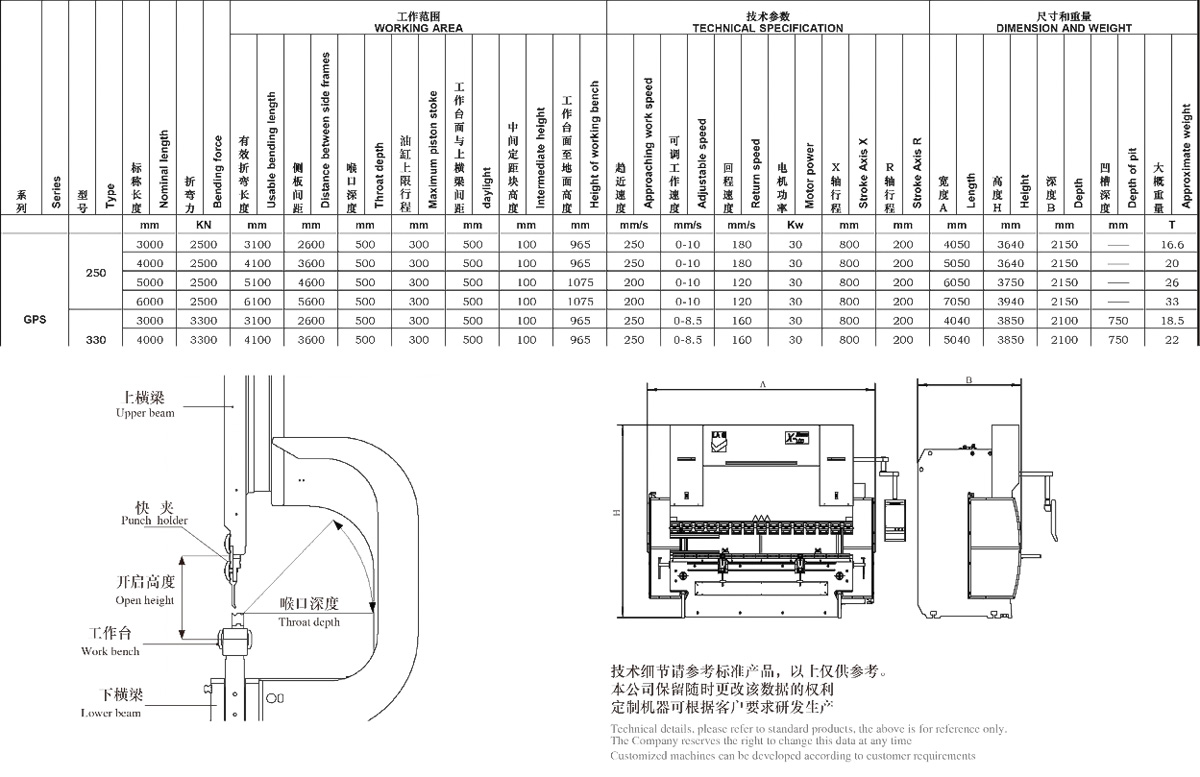

LAG is recognized as a famous builder of press brake worldwide and its new GPS series press brakes enable you to fabricate parts in any format,from the simplest to the most complex,precisely and cost-effective

State-of the-art machine construction

A common feature to all GPS series press brakes is a modular design platform, wealth of experience, modular machining bolted stable machine frame and the latest in control technology Unique, technological LAG heavy frame material S45C built with bolted elements long life

PATENTED FRAME PROPORTIONAL DEFLECTION COMPENSATION SYSTEM G-flex

With added G-Flex system, the actual position ofthe upper beam is measured by the two linear encoders installed on auto balanced lever on t o p of the "C-shaped" sub-frames. That mechanism does not follow any of the deformation of the frame during the bending therefore the measurement imprecision of the encoder caused by the yawning of the side frames is completely eliminated by the spring loaded mechanism

X-CS

Self balancing and crowning system This system compensates the deflections of the lower beam; it is synchronized with the G-Flex device; during bending phase, although lengths and positioning of parts varies, parallelism is still guaranteed. Programming or parameters are required by the operator throught CNC.

Back gauge synchronized axes GP-2(X-R)

As a rear gauge system to ensure dimensional accuracy of bending products, it is another important part of the bending machine. GPS series of standard models of 2 axis (X-R) rear gear to ensure that the most flexible, most accurate and high speed to complete almost all complex bending workpiece positioning required

O. Also according to the request of 4 axis (X-R-Z1-Z2) ofRear; unique to plate precision machining surface as the base surface mounting linear guide and precision gear rack drive, without any adjustment to ensure that the stopper beam around the supporting surface parallelism. As a result of patented backlash elimination gear rack drive, the fastest speed of up to 500mm/s;

Precision steel after transverse left and right support seat through the wedge mechanism respectively on X axis and R axis precision fine-tuning, embodies the highest pursuit of the bending process LAG;

Highly integrated LAG, the latest patented design of the X-R shaft full closed self lubrication integral transmission, using a straight double drive transmission mode, to achieve safe and reliable transmission, while ensuring the right and left direction of synchronization accuracy.

-X axis travel 800mm; moving speed up to 500mm/s

-R axis travel 200mm; moving speed up to 250mm/s

LAG bending machine after stopping finger equipped with collision avoidance system when malfunctions caused by the impact, after retaining that occurs when the stopping finger block will disengage from the base, to avoid precision ofRear damage, at the same time history to ensure the personal safety of the operator

Retractable pneumatic supports

The GRP -R pneumatic sheet supports combined fixed along each Z1/ Z2 CNC moving finger extend out on request to support thinner sheet metal blanks that would otherwise be falling off behind the bottom die and hard to lie against the back gauge fingers. As soon as bending starts, the GPR -R retracts into rear position. This will prove very useful for bending large panels as the operator can feed the material in the same direction for continuous bending, and avoid most of the parts turning operation. Bending efficiency and precision is greatly improved

The brushes on t o p of the GRP-R supportsprevent material scratching or marking

Manual sliding front supports

Modular and highly rigid, the front supports are manually sliding along the lower beam of the press on linear guides and a roller bearing at the bottom. The height is easily adjusted using a front located handle. You can also order some parking areas for those supports when required

Punch Holder

Standard KYOKKO H=100 mm high precision manual quick clamping, compatible with European, Amada, Japanese and domestic type tools. One operator can quickly change and clampvertically orfrom the side any uppertool. Optional versions available with double quick clamping or with H=150 mm

Lower tool clamping G-BLOCK M

Standard manualclamping

Quick change dies eliminate need to align punch and die when a die is changed Base is 60mm wide, allowing installation of standard European 4-V dies, T-dies, etc

Modular tooling system

According to your required bending needs and the commonly used sheet thickness, LAG engineers, according to the open height and press brake can recommend the best selection, including:

standard Punch 1 set

standard V-Die 1 set

The quick change base with T-shape 1 set

Customers can select other tools according to their needs

Safety-CE certification

The G- T O P press brakes are equipped with the most advanced safety solutions for press brakes in terms of productivity and safety.

In addition to meeting relevant standards and regulations, the safety installation of this press are equipped with CE high-end electrical and hydraulic components, such as the DSP-AP Laser Beam, electronic and hydraulic redundant systems

DSP-AP Laser Safety offers unique features, increasing the productivity of the press brake:

? Speed change point at 2 mm above material (0.2 sec), allowing the operator to work safely even with fingers close to the tools without interrupting high approaching speed

? Built in tool crash protection

? Box mode capability to achieve complex shapes without significant impact on speed

? Different operating modes selectable bend by bend (stop at mute-auto mute) fully integrated in the control

? Height adjustable supports through linear guided sturdy supports equipped with quick reference scale for faster tool changes and repositioning along with upper position locking mechanism allowing side extraction

Heating exchanging system

Another important competitive advantage of the hydraulic system comes from the use of a separate automatic oil cooling system. Hydraulic oil temperature upper limit is monitored by temperature sensors to control oil temperature within reasonable range. Automatic start-stop function effectively protects the cooling and hydraulic systems during long working hours preventing overheating of the oil than can cause permanent damages to valves or seals and reduce equipment performance

Independent crowing pump

In order to manage perfectly the crowning pressure, a secondary hydraulic pump is in line with the main pump in order to control the working pressure independently. This ensures constant bending accuracy

Air conditioning electrical box

The electric cabinet is equipped with an air conditioning system that controls the temperature and humidity to an ideal level. It also prevents dust and corrosive gases from entering the cabinet and damaging electrical or electronical components. This guarantees a longer life to all components and improves the system stability and machine reliability

Numerical control system ESA 540 PC touch screen

LAG cooperates with world famous Numerical Controls manufacturers. State of the art control technology combined with LAG's decades of bending know-how allow operators to easily program a wide variety of parts under different bending conditions.

Ease of programming

An operator friendly 15" Touch Screen user interface leads to a significant improvement in data input rate and greatly reduce programming time 2D graphical programming with automatic bendingsequencing will assist in making even first time operators become quickly autonomous.

Productive

the ESA540PC has perfect dynamic crowning software,a large memory CIF card,two USB ports and an Internet connectivity Most bending applications are easy to program by using the 2D graphical on-line programming with auto sequencing. According to demand in the course of time the designer may do simulation checks using the 3D visualization of the parts on the machine control

2D Off-line software

2D offline software is an easy-to-use and an effective tool for off-line programming of all G- T O P series press brakes

Main Standard Configuration

Frame proportional deflection compensation system G-Reflex

Traditional hydraulic system X-CS

CNC mod. ESA540PC / Delem 58T

4+1 axis (Y1-Y2-X-R+C)

Heavy back gauge system mod. GP-2(X-R)

2 fingers on back gauge support

CE standard double shift foot pedal

Telephonee:

+86 13705384901

Build Geshi international technology brand

CONTACT US

Tel:+86 13705384901 +86 18953813118 +86 0538-6089096 +86 0538-6089189

E-mail:[email protected]

Add:South of Kuixing Road, north of Xingfu Road, Ciyao Town, Ningyang County, Tai'an City, Shandong Province, China